Wine Cellar Construction Using Eco-Friendly Materials and Reliable Wine Cooling Units

Contents

- 1Using Green Building Materials and Reliable Wine Cellar Cooling Units in Wine Cellar Construction

- 1.1Reclaimed Oak Wine Barrels

- 1.1.1Wine Barrel Products: Flooring, Wine Racks, Countertops, and Art Pieces

- 1.2Nautical Timbers for Wine Cellar Flooring

- 1.3High-Grade Wine Cellar Cooling Units

- 2Work with Wine Cellar Construction Experts

Our Experts in Wine Cellar Construction Installs Eco-Friendly Features and Reliable Wine Cellar Cooling Units

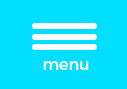

One of the crucial aspects of quality wine cellar construction is creating a functional and appealing design that suits the client’s requirements. Building a wine cellar requires extensive knowledge and skills in preparing the room for refrigeration and creating a design that will enhance the aesthetic value of the home. At Custom Wine Cellars Los Angeles, we recommend incorporating green building materials and installing an efficient wine cellar cooling system from top-notch manufacturers in your wine cellar.

Using Green Building Materials and Reliable Wine Cellar Cooling Units in Wine Cellar Construction

Integrating a wine cellar into your home will not only provide a safe storage space for your prized collection but will also enhance the visual appeal and increase the resale value of your home.

As one of the master builders in California, Custom Wine Cellars Los Angeles aims to create innovative wine cellar designs for avid wine collectors who want a unique and functional wine room for their collection. Our team recommends using eco-friendly building materials and high-grade wine cellar cooling units.

Green building materials are recycled products that do not have any adverse effects on the environment. These sustainable products are highly recommended in wine cellar construction.

At Custom Wine Cellars Los Angeles, our master builders have found a way to recycle oak wine barrels and nautical timbers for creating distinct-looking wine rooms. We want to help minimize the amount of new raw materials produced and reduce waste products thrown into landfills. Using sustainable materials will have a positive impact on our environment.

Moreover, we also want to ensure that every wine cellar we build is designed to provide the optimum conditions needed for proper wine aging.

Reclaimed Oak Wine Barrels

Oak wine barrels have long been used for fermenting and aging wines. Doing this will enhance the flavor of the wine stored in the barrel. Oak wine barrels impart a hint of vanilla, caramel, or cream on the wine. After five to seven years of serving their purpose, these oak wine barrels are typically used as firewood or planters, while some are dumped into landfills.

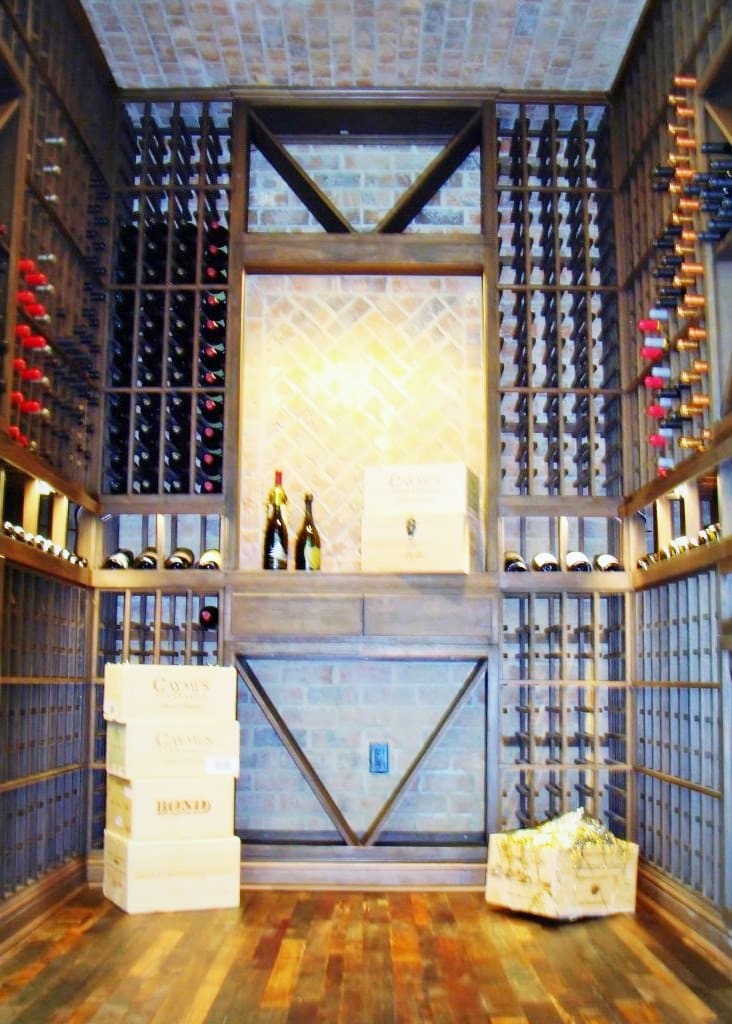

The retired wine barrels are broken into three components, which are used for creating unique wine cellar flooring, wine racks, countertops, and art pieces. We utilize all of the parts of the wine barrel, so nothing goes to waste.

Cooperage makes use of the top and bottom sections of the oak barrels. It exhibits cooper stamps consisting of the name of the vineyard, winery logo, and description of the wine stored in the barrel.

Stave comes from vertical wood from the sides of the oak wine barrels. The strips or planks of wood have distinctive marking left by the metal bands or hoops that hold the sides of the barrel together.

Infusion consists of the inner parts of the barrel, which exhibit whitish, pinkish, and reddish tones imparted by the wine stored in it.

Wine Barrel Products: Flooring, Wine Racks, Countertops, and Art Pieces

To create sustainable products for wine cellars, the wine barrels are broken into long strips with about 5/8-inch thickness. The pieces of wood differ in width and length. We micro-bevel the planks to hide the unequal heights and smoothen the surface of the wood pieces.

At Custom Wine Cellars Los Angeles, we collaborate with professional builders like Coastal Custom Wine Cellars and Blue Grouse Wine Cellars in wine cellar construction. They have been in the wine cellar industry for many years and have proven their expertise in designing eco-friendly wine rooms. They have created beautiful wine barrel features for wine cellars like flooring, wine racks, countertops, and wine barrel art.

When making wine barrel art pieces, the barrelheads are carved by a skilled artisan. They are attached to a wooden backing for structural integrity. Common designs that can be carved on a wine barrel art piece are grapes, winery, winery logos, and wine glasses.

Nautical Timbers for Wine Cellar Flooring

Another way to integrate a sustainable product into your wine cellar is by using nautical timbers for your flooring. These timbers can be found in the hulls of ships consisting of cribbage and ballasts. However, modifications were made in the ballast systems of ships, making nautical tiers obsolete.

Instead of discarding them, they are reprocessed so they can be used as green building materials. Aside from durability and strength, flooring from antique nautical timbers look good in any wine cellar design.

High-Grade Wine Cellar Cooling Units

Custom Wine Cellars Los Angeles always wants to ensure that our client’s collections are kept safely in a refrigerated wine cellar. We use wine refrigeration units from trusted manufacturers like Wine

Guardian, WhisperKOOL, US Cellar Systems, and CellarPro. All of their climate control systems are designed with commercial-grade components and functional features for superior cooling performance.

We will perform a heat load calculation to determine the correct size of the wine cooling system for your wine cellar. Choosing the wrong size and type of refrigeration unit will cause wine storage problems in the future.

Work with Wine Cellar Construction Experts

Are you planning to build a safe wine storage room for your collection and help save the environment? At Custom Wine Cellars Los Angeles, we use and recommend using green building materials like reclaimed wine barrels and nautical timbers in wine cellar construction. We offer efficient wine cellar cooling units supplied by trusted manufacturers.

If you need help or have any questions about wine room construction, please call us at + 1 (323) 825-9846.